Discover the Benefits of Sustainable Metal Bonding Today!

In the realm of manufacturing and construction, understanding sustainable metal bonding techniques is crucial for fostering an eco-friendly approach. These techniques not only enhance the longevity and performance of metal components but also significantly reduce environmental impact. Sustainable metal bonding involves utilizing adhesives and methods that minimize waste and energy consumption while maximizing strength and durability.

Some of the most prominent sustainable bonding techniques include:

- Cold welding: This technique joins metals without heat, reducing energy use and preventing thermal distortion.

- Adhesive bonding: Environmentally friendly adhesives are employed to bond metals, offering resistance to corrosion and vibration.

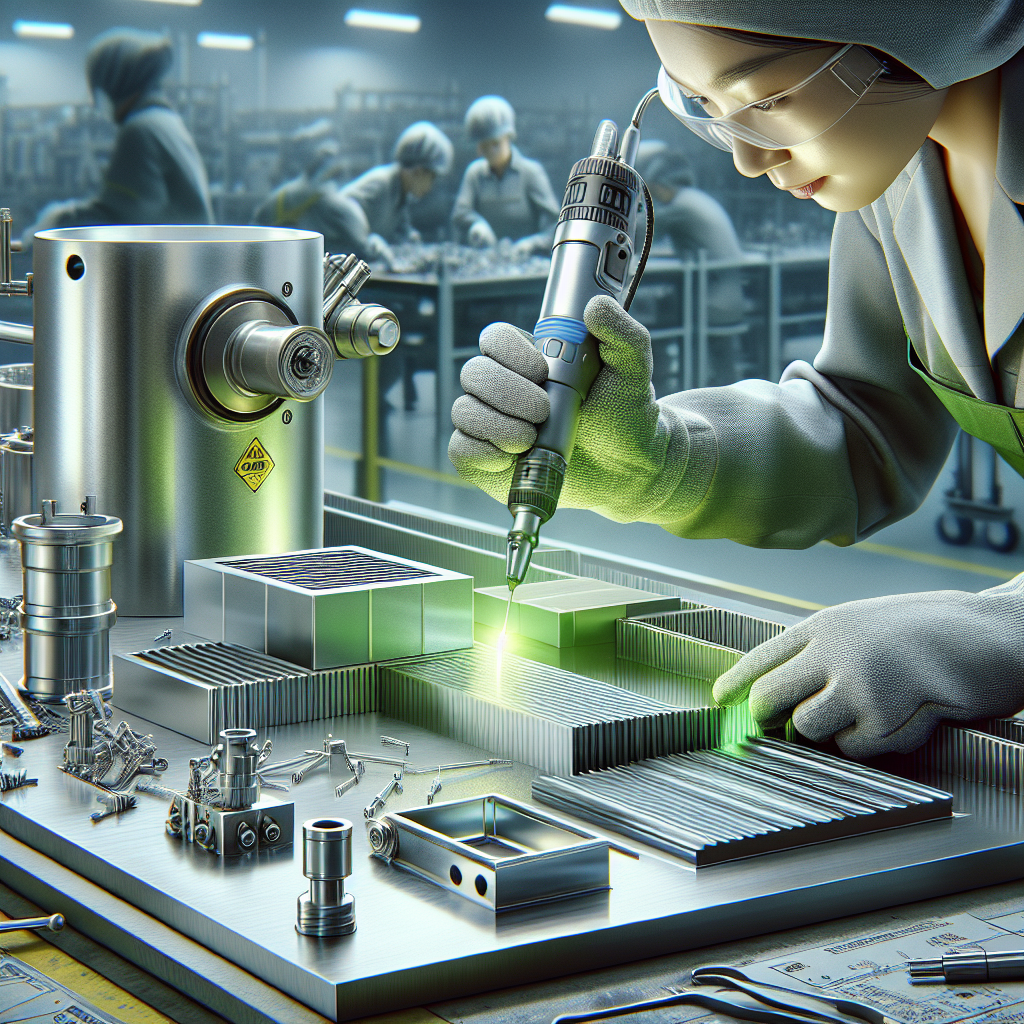

- Laser welding: This method uses focused laser beams to join metals with precision, resulting in less material waste and a cleaner process.

By incorporating these techniques into their operations, industries can achieve a dual benefit: enhancing product performance while contributing to sustainability. As businesses strive to meet regulatory standards and consumer demands for greener practices, the adoption of sustainable metal bonding becomes increasingly essential.

To explore more about how our planet-friendly lubricants can support your sustainable initiatives, visit us at planetsafelubricants.com.

Environmental Benefits of Sustainable Metal Bonding

The adoption of sustainable metal bonding techniques presents numerous environmental benefits that align with global sustainability goals. By leveraging these innovative methods, industries can significantly reduce their ecological footprint while maintaining high-performance standards.

One of the primary environmental advantages is the reduction of carbon emissions. Traditional metal bonding processes often require high temperatures and extensive energy consumption, leading to increased greenhouse gas emissions. In contrast, sustainable methods such as cold welding and adhesive bonding utilize less energy, thereby minimizing their impact on the environment.

Additionally, sustainable metal bonding techniques contribute to waste reduction. Conventional methods may generate scrap metal and other waste materials that require disposal. Sustainable practices focus on precision and efficiency, resulting in less waste and promoting a circular economy approach where materials are reused and recycled.

Another significant benefit is the enhancement of product lifespan. By using environmentally friendly adhesives and bonding techniques, manufacturers can create products that are more resistant to corrosion, wear, and fatigue. This durability not only reduces the need for replacements but also lowers the overall resource consumption associated with manufacturing new products.

Ultimately, the shift towards sustainable metal bonding is a proactive step towards a greener future, fostering a balance between industrial growth and environmental conservation.

Performance Advantages of Sustainable Metal Bonding

When it comes to sustainable metal bonding, the performance advantages are equally compelling as the environmental benefits. These advanced bonding techniques not only support eco-friendly initiatives but also enhance the overall functionality and durability of bonded materials.

One of the key performance benefits is the improved strength of the bond. Sustainable metal bonding methods often utilize high-quality adhesives that provide exceptional adhesion properties. This results in joints that are not only strong but also resistant to various stresses, including thermal expansion, vibration, and impact.

Furthermore, sustainable bonding techniques can offer superior flexibility compared to traditional welding or mechanical fastening. This flexibility allows bonded assemblies to withstand dynamic loads and thermal cycling without compromising structural integrity. Such adaptability is especially crucial in applications within demanding environments, such as aerospace and automotive industries.

Another significant advantage is the reduction of distortion and stress in the bonded materials. Traditional bonding methods, like welding, can introduce heat and cause warping. In contrast, sustainable bonding processes maintain lower thermal impact, preserving the dimensional accuracy and physical properties of the materials involved.

Lastly, the compatibility of sustainable bonding solutions with a wide range of materials—including metals, plastics, and composites—provides manufacturers with greater design freedom. This versatility allows for innovative product designs that can meet specific performance requirements while adhering to sustainability goals.

Cost-Effectiveness of Sustainable Metal Bonding Solutions

In today's competitive market, cost-effectiveness plays a crucial role in the adoption of any manufacturing technique, including sustainable metal bonding. Organizations are increasingly looking for solutions that not only enhance performance but also contribute to their bottom line.

One of the primary ways sustainable metal bonding solutions prove to be cost-effective is through reduced materials waste. Unlike traditional methods such as welding, which often require additional materials for reinforcement or repair, sustainable bonding techniques minimize excess material usage. This leads to lower material costs and less waste, aligning with economic and environmental goals.

Additionally, the speedy application of sustainable bonding solutions can significantly reduce labor costs. The ease of application means that less time is spent on the bonding process. Moreover, the need for extensive post-bonding processes—such as grinding, finishing, or painting—is often minimized, further cutting down overall labor costs.

Another advantage lies in the long-term durability and reliability of bonded joints. Sustainable metal bonding typically results in stronger and more resilient assemblies, which translates to decreased maintenance and repair costs over time. By investing in high-quality bonding solutions, companies can extend the lifespan of their products and reduce the frequency of costly repairs or replacements.

Finally, as sustainability becomes a key focus in many industries, companies that adopt eco-friendly practices often enjoy enhanced brand reputation and customer loyalty. This not only opens up new market opportunities but can also justify a premium pricing model, ultimately leading to greater profitability.

Applications of Sustainable Metal Bonding Across Industries

The versatility of sustainable metal bonding makes it a preferred choice across various industries. From automotive to aerospace, and construction to electronics, these bonding solutions offer innovative methods that enhance product performance and sustainability.

In the automotive industry, sustainable metal bonding is utilized to create lightweight structures that improve fuel efficiency without compromising safety. By replacing traditional welding with advanced bonding techniques, manufacturers can reduce vehicle weight and enhance overall performance while also cutting down on energy consumption during production.

The aerospace sector benefits significantly from sustainable metal bonding as well. The need for high-strength and lightweight materials is paramount in aerospace applications. Bonding solutions ensure that components can withstand extreme conditions while maintaining structural integrity, which is crucial for safety and efficiency in air travel.

In construction, sustainable metal bonding is used in prefabricated buildings and modular construction. These methods allow for quicker assembly, reduced waste, and lower energy use throughout the construction process. The ability to bond dissimilar materials also opens up new design possibilities that enhance architectural innovation.

The electronics industry employs sustainable metal bonding in the manufacturing of circuit boards and electronic devices. By using eco-friendly adhesives, manufacturers can ensure long-lasting connections while also adhering to stringent environmental regulations. This approach not only improves product reliability but also meets consumer demand for sustainable products.

Overall, the applications of sustainable metal bonding are vast and varied, reflecting a growing trend towards eco-friendly practices across industries. As more companies recognize the benefits of these solutions, we can expect to see continued innovation and adoption in the years to come.

Choosing the Right Sustainable Metal Bonding Products

When it comes to selecting the right sustainable metal bonding products, several factors should be considered to ensure optimal performance and environmental compliance. The right choice can significantly impact the effectiveness of your application and the sustainability of your processes.

First, assess the specific requirements of your project. Different applications may require various types of bonding agents, such as adhesives, sealants, or coatings. Understanding the materials involved and the conditions they will be subjected to—such as temperature fluctuations, moisture exposure, and mechanical stress—will guide you in selecting the most suitable product.

Next, look for products that are certified as environmentally friendly. Certifications from reputable organizations can provide assurance that the bonding agents meet stringent safety and performance standards. Products labeled as non-toxic, non-hazardous, and odor-free ensure a safer working environment for your team and contribute to a healthier planet.

Additionally, consider the application method. Some sustainable metal bonding products are designed for easy application, which can save time and labor costs during installation. Check if the product is compatible with your existing equipment and processes to maximize efficiency.

Finally, consult with suppliers and manufacturers who specialize in sustainable solutions. They can offer valuable insights into the latest advancements and help you choose products tailored to your specific needs. For top-quality sustainable metal bonding products that prioritize both performance and environmental responsibility, visit us at planetsafelubricants.com, where you can explore our extensive range of eco-friendly options designed for various industries.

0 comments